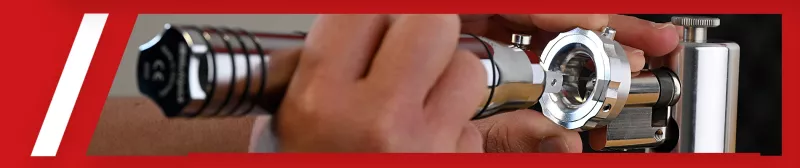

Special Safe Drills

The requirements for drilling tools used in vault technology are particularly high and varied.

The manufacturers of good, modern safes like to use composite armor plates or manganese steel to withstand the attack of a cutting/peeling drilling tool, but the filling between the inner and outer safe wall can also be "tough" - it often contains combinations of plastic granulate and/or concrete, mixed with aggregates such as ceramic, quartzite, carborundum particles or basalt, but also looser fillings of steel balls, rollers, ceramic bodies and similar "nasties" can be found in this gap, all of which are intended to fulfill only one task - to thwart a drilling attack on the safe!

However, safes have the disadvantage that they can only be opened as long as their locking mechanism is not defective and the key(s) or combination required to open them are still available. - This can be remedied by a safe technician. If the safe cannot be opened without destroying it, but is to be used again afterwards, the minimally invasive method of drilling in the right place(s) and then permanently and securely closing the hole(s) remains.